Air Testing is used to test and

analyze the air in a workplace. This could be in a construction zone, office,

government building, school, mall, or anywhere else where business takes place

or people live. Although air testing has

not always existed, it is now essential in our day to day lives because of all

of the chemicals and pollutants that exist today that are hazardous to our

health. Poor air quality can lead to unfortunate health changes in the

environment and in individual’s bodies. Results for exposed people can range

from sore eyes, burning in the nose and throat, nausea and headaches. Extreme

results could be allergies, heart disease, cancer and other longer-term

diseases/results. Employers who do not comply with air quality standards get in

legal trouble.

Molds, bacteria, asbestos, dust, gases and fumes, pesticides

and other chemicals are examples of common air pollutants found in buildings in

workplaces.

Pump Callibration is the process of using a metering instrument

to determine the airflow rate created by the sample collector. Callibration of

the flow of a sample through the sampling is important and needs thoroughly

checked before and after each sample. In class, we did a benzene sampling test.

We used the formula included in the associated powerpoint to calculate our

answer, and after the math was done, our answer equaled 14.7, or two liters per

minute. 0.75parts per million (PPM) is less than the occupational exposure

limit, meaning it was in acceptable amounts in our classroom. We were not

overexposed to benzene in class.

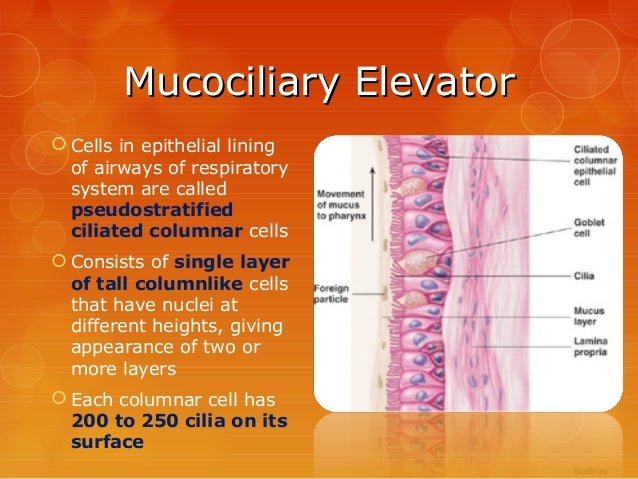

The “breathing zone” is technically the

five to ten inch radius surrounding a worker’s nose and mouth. This area is specifically

targeted because the mouth and nose are the modes of entryway through

inhalation and ingestion.

As mentioned above, some substances will not show effects

for years after exposure. For example, asbestos can linger in the inhalant’s

lungs and eventually cause irreversible damage to their health and life

longevity.

Occupational exposure limit, or OEL, is determined by OSHA. Occupational Safety and Health Administration, or OSHA, is a part

of the United States Department of Labor. The OSHA administrator is the

Assistant Secretary of Labor for Occupational Safety and Health. OSHA deals

with assuring the health standards of the workforce by setting and enforcing

standards to protect people. Other tasks involve training, outreach, educating

and assisting the workforce.

On the Center for Disease Control and Prevention’s webpage

is listed the National Institute for Occupational Safety and Health, (NIOSH) .

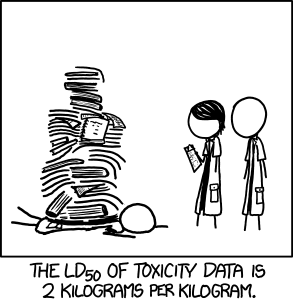

There are different methods to testing substances in the workplace’s air,

surfaces, and blood and urine of the workers there.

When testing, the flow rate, sample’s stability and sample

itself impact the outcome of the test. Flow rate is the volume of fluid which

passes per unit of time. Sample stability is the capability of a material to

retain the initial property of a measured constituent for a period of time

within a certain time period. Instability is present when a change occurs in

one of the measurements taken.